Όλα τα Προϊόντα

-

Κεραμικά ρουλεμάν

-

608 κεραμικά ρουλεμάν

-

Υβριδικά κεραμικά ρουλεμάν

-

Κεραμικά ρουλεμάν κυλίνδρων

-

Κεραμικό ρουλεμάν ώθησης

-

Κεραμική συμπεριφορά ολίσθησης

-

Προηγμένη δομική κεραμική

-

Σφαίρα νιτριδίων πυριτίου

-

Σφαίρα καρβιδίου του πυριτίου

-

Κεραμική σφαίρα Zirconia

-

Ρουλεμάν καρβιδίου του πυριτίου

-

Ένσφαιρος τριβέας νιτριδίων πυριτίου

-

Κεραμικό ρουλεμάν Zirconia

-

Μηχανική σφράγιση

-

Ρουλεμάν καρβιδίου του πυριτίου

-

RobertaΤα κεραμικά ρουλεμάν τους είναι υψηλής ακρίβειας, καλή ποιότητα και ανέξοδος. Έχουμε τη συνεργασία για πολλά χρόνια.

RobertaΤα κεραμικά ρουλεμάν τους είναι υψηλής ακρίβειας, καλή ποιότητα και ανέξοδος. Έχουμε τη συνεργασία για πολλά χρόνια. -

Όλγα WeinbergΑυτή η επιχείρηση είναι ο αξιόπιστος και επαγγελματικός προμηθευτής κεραμικών ρουλεμάν μας για πολλά χρόνια, τα κεραμικά ρουλεμάν τους, τα οποία χρησιμοποιούνται στην αντλία μας είναι καλά στην ποιότητα.

Όλγα WeinbergΑυτή η επιχείρηση είναι ο αξιόπιστος και επαγγελματικός προμηθευτής κεραμικών ρουλεμάν μας για πολλά χρόνια, τα κεραμικά ρουλεμάν τους, τα οποία χρησιμοποιούνται στην αντλία μας είναι καλά στην ποιότητα.

Υπεύθυνος Επικοινωνίας :

Cooper wang

Τηλεφωνικό νούμερο :

86 15801087509

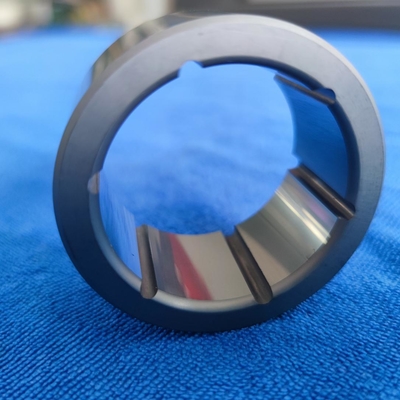

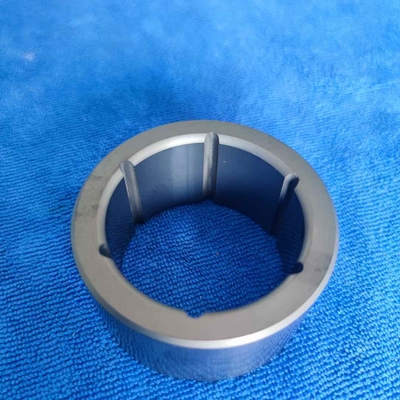

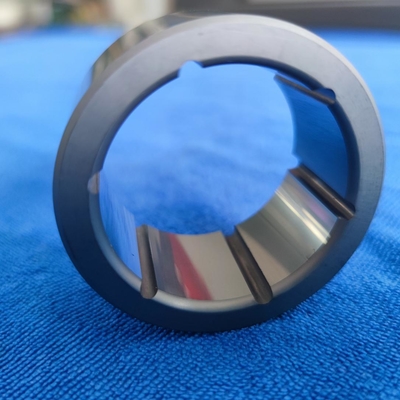

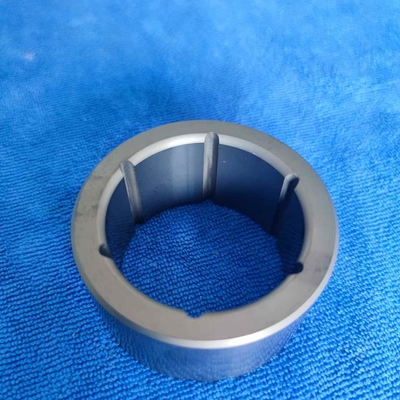

Κεραμικά συρρικνωτικά ρουλεμάν του καρβιδίου του πυριτίου προσαρμοσμένα για περιβάλλον υψηλής θερμοκρασίας

| Τόπος καταγωγής | Κίνα |

|---|---|

| Μάρκα | CSQ |

| Πιστοποίηση | FDA,REACH,ROHS,ISO9001,ISO14001,ISO45001 |

| Αριθμό μοντέλου | προσαρμοσμένα προϊόντα |

| Ποσότητα παραγγελίας min | 20-50 PC |

| Τιμή | negotiable |

| Συσκευασία λεπτομέρειες | Πηλίδα+Καρτόνι |

| Χρόνος παράδοσης | 20-45 ημέρες εργασίας |

| Όροι πληρωμής | Τ/Τ |

| Δυνατότητα προσφοράς | 2000 κομμάτια το μήνα |

Με ελάτε σε επαφή με δωρεάν δείγματα και δελτία.

Whatsapp:0086 18588475571

wechat: 0086 18588475571

Skype: sales10@aixton.com

Εάν έχετε οποιαδήποτε ανησυχία, παρέχουμε τη 24ωρη σε απευθείας σύνδεση βοήθεια.

xΛεπτομέρειες

| Ονομα | Προσαρμοσμένο κεραμικό ρουλεμάν με μανίκι | Κατηγορία | Κεραμικό συρόμενο ρουλεμάν |

|---|---|---|---|

| Υλικό | Καρβίδιο πυριτίου | Μέγεθος | Προσαρμοσμένο, σύμφωνα με τα σχέδια |

| Εφαρμογή | Γοβάκια | Πακέτο | Κουτί αφρού+χαρτοκιβωτίων |

| Ποιότητα | Υψηλή ακρίβεια, μεγάλη διάρκεια ζωής, OEM Serive | Προσδιορισμός | Τυπικό μέγεθος και προσαρμοσμένο |

| Επισημαίνω | Κεραμικά ρουλεμικά ρουλεμικά από καρβίδιο του πυριτικού,Κεραμικά ρουλεμάν υψηλής θερμοκρασίας,Προσαρμοσμένα κεραμικά δακτυλίδια ρουλεμάν |

||

Μπορείτε να σημειώσετε τα προϊόντα που χρειάζεστε και να επικοινωνήσετε μαζί μας στον πίνακα μηνυμάτων.

Περιγραφή προϊόντων

Κεραμικά συρόμενα μανίκια καρβιδίου πυριτίου προσαρμοσμένα για περιβάλλοντα υψηλής θερμοκρασίας

| Ιδιότης | Αξία |

|---|---|

| Ονομα | Προσαρμοσμένο κεραμικό ρουλεμάν με μανίκι |

| Κατηγορία | Κεραμικό συρόμενο ρουλεμάν |

| Υλικό | Καρβίδιο πυριτίου |

| Μέγεθος | Προσαρμοσμένο, σύμφωνα με τα σχέδια |

| Εφαρμογή | Γοβάκια |

| Πακέτο | Κουτί αφρού + χαρτοκιβωτίων |

| Ποιότητα | Υψηλή ακρίβεια, μεγάλη διάρκεια ζωής, υπηρεσία OEM |

| Προσδιορισμός | Τυπικό μέγεθος και προσαρμοσμένο |

Επισκόπηση προϊόντων

Τα μανίκια καρβιδίου πυριτίου (SIC) είναι κεραμικά συστατικά υψηλής απόδοσης που κατασκευάζονται από το SIC. Παρουσιάζουν εξαιρετική αντοχή στη φθορά, αντοχή στη διάβρωση, υψηλή σκληρότητα και θερμική σταθερότητα, καθιστώντας τα ιδανικά για ρουλεμάν, σφραγίδες και συστήματα μετάδοσης σε σκληρά περιβάλλοντα σε βιομηχανίες όπως η χημική επεξεργασία, τα μηχανήματα, οι ημιαγωγοί και η ενέργεια.

Βασικές ιδιότητες

| Μέγιστη θερμοκρασία | Έως 1650 ℃ |

| Πυκνότητα | 3.15-3.18 g/cm3 |

| Θερμική διαστολή | 4.0 (10-6/℃) |

| Θερμική αγωγιμότητα | 120 w/m ° k |

| Σκληρότητα | 2800 HV5 |

| Ελαστικό μέτρο | 410 GPA |

| Χημική σταθερότητα | Ανώτερη αντίσταση σε οξύ και αλκαλική διάβρωση (συμπεριλαμβανομένου του υδροφθορικού οξέος) |

Αιτήσεις

- Χημική βιομηχανία:Αντλίες, βαλβίδες, σφραγίδες αντιδραστήρα

- Μηχανήματα:Ρουλεμάν υψηλής ταχύτητας, εξαρτήματα ακριβείας

- Ημιαγωγοί:Χειρισμός πλακιδίων

- Νέα ενέργεια:Φωτοβολταϊκός και εξοπλισμός παραγωγής μπαταρίας λιθίου

Πλεονεκτήματα όλων των κεραμικών ρουλεμάν έναντι εδράνων χάλυβα

1. Υψηλότερη αντοχή στη θερμοκρασία

Τα κεραμικά έδρανα διατηρούν ανώτερη μηχανική σταθερότητα σε αυξημένες θερμοκρασίες, καθιστώντας τα ιδανικά για ακραίες εφαρμογές θερμότητας όπου τα έδρανα χάλυβα θα υποβαθμίσουν.

2. Ανώτερη απόδοση σε θερμική ποδηλασία

Λόγω του χαμηλού συντελεστή θερμικής διαστολής τους, τα κεραμικά ρουλεμάν αντιμετωπίζουν ελάχιστες αλλαγές κάθαρσης κάτω από διακυμάνσεις της θερμοκρασίας, εξασφαλίζοντας αξιόπιστη λειτουργία σε ένα ευρύτερο φάσμα συνθηκών.

3. Ενισχυμένες ιδιότητες κατά της κατάχρησης και αντι-jamming

Η μειωμένη θερμική παραμόρφωση των κεραμικών υλικών ελαχιστοποιεί τη δέσμευση που προκαλείται από την τριβή, βελτιώνοντας σημαντικά την αντίσταση στην κατάσχεση και τη χάλια.

4. Δυνατότητα λειτουργίας χωρίς λάδι

Τα κεραμικά ρουλεμάν παρουσιάζουν ιδιότητες αυτοελέγχου και μπορούν να χρησιμοποιήσουν μέσα διεργασίας για λίπανση, επιτρέποντας αξιόπιστες επιδόσεις σε περιβάλλοντα υψηλής βάσης ή όπου η παραδοσιακή λίπανση είναι ανέφικτη.

5. Εξαιρετική αντοχή στη διάβρωση

Σε αντίθεση με τον χάλυβα, τα κεραμικά είναι αδιαπέραστα σε οξέα, αλκαλικά και άλατα, καθιστώντας τα τέλεια για σκληρή χημική επεξεργασία, θαλάσσια και διαβρωτικές βιομηχανικές εφαρμογές.

6. Ηλεκτρική μόνωση & αντι-στατικές ιδιότητες

Τα κεραμικά μας ρουλεμάν είναι μη αγώγιμα, εξαλείφοντας τη στατική εκκένωση και αποτρέποντας τα ηλεκτρικά ζημιές-συνηθισμένα προβλήματα με αγώγιμα έδρανα χάλυβα.

7. Μη μαγνητική και ανθεκτική στη μόλυνση

Η μη μαγνητική φύση του Ceramic αποτρέπει την προσκόλληση μαγνητικών σωματιδίων, τη μείωση της λειαντικής φθοράς και τη διασφάλιση της ομαλής λειτουργίας σε εξοπλισμό μαγνητικής τομογραφίας, εργαλεία ημιαγωγών και άλλα μαγνητικά ευαίσθητα περιβάλλοντα.

Γιατί να μας επιλέξετε

Έχουμε τρία εργοστάσια στην Κίνα για να ανταποκριθούμε σε διαφορετικές ανάγκες των πελατών, εξοπλισμένα με προχωρημένες μηχανές συμπίεσης, πυροσυσσωμάτωσης και επεξεργασίας. Η εταιρεία μας διαθέτει έντεκα διπλώματα ευρεσιτεχνίας εφεύρεσης για μοντέλα κοινής ωφέλειας και διαθέτει μια επαγγελματική ομάδα για την παροχή υψηλής ποιότητας προσαρμοσμένα προϊόντα ρουλεμάν.

Από το 1982, έχουμε συγκεντρώσει πάνω από 40 χρόνια εμπειρίας στην παραγωγή κεραμικού ρουλεμάν, βελτιώνοντας συνεχώς τα υλικά μας, τις τεχνικές επεξεργασίας και τον εξοπλισμό. Έχουμε γίνει μια κορυφαία επιχείρηση στην αγορά κεραμικών και κεραμικών προϊόντων της Κίνας.

Έχουμε εκτεταμένη εμπειρία που παράγει συρόμενα ρουλεμάν καρβιδίου πυριτίου για αντλίες ταχύτητας, συμπεριλαμβανομένων των προμηθειών στο Witte της Γερμανίας για πολλά χρόνια.

Τα πλεονεκτήματα μας ρουλεμάν

- Διατίθενται δωρεάν ρουλεμάν δείγματα

- Συμβατό με πρότυπο ISO

- Έτοιμα ρουλεμάν για παράδοση

- Οι μικρές ποσότητες παραγγελιών έγιναν αποδεκτές

- Διαθέσιμη υπηρεσία ρουλεμάν OEM

- Προσαρμοσμένα έδρανα σύμφωνα με σχέδια ή δείγματα πελατών

- Ανταγωνιστική τιμολόγηση εργοστασίων

Συχνές ερωτήσεις

Ε: Ποιοι είμαστε;

Α: Είμαστε εργοστάσιο στο Πεκίνο της Κίνας με πάνω από 40 χρόνια εμπειρίας που παράγει κεραμικά ρουλεμάν, έχοντας καθιερώσει σχέσεις συνεταιρισμού με πολλές εγχώριες και ξένες εταιρείες.

Ε: Πώς μπορούμε να εγγυηθούμε την ποιότητα;

Α: Παράγουμε δείγματα πριν από τη μαζική παραγωγή, ακολουθούμε αυστηρά τις απαιτήσεις των πελατών, χρησιμοποιούμε εξοπλισμό επιθεώρησης ακριβείας και χρησιμοποιούμε διπλή συσκευασία (αφρό + χαρτοκιβώτιο) για να εξασφαλίσουμε την ποιότητα του προϊόντος.

Ε: Τι μπορείτε να αγοράσετε από εμάς;

Α: Προσφέρουμε κεραμικά ρουλεμάν με μπάλα βαθιάς αυλάκωσης, ρουλεμάν γωνιακής επαφής, υβριδικά κεραμικά ρουλεμάν, γραμμικά ρουλεμάν και διάφορες κεραμικές μπάλες.

Ε: Γιατί πρέπει να αγοράσετε από εμάς;

Α: Ως βιομηχανία και εμπορική ολοκληρωμένη εταιρεία με τρία εργοστάσια και σύγχρονο εξοπλισμό παραγωγής, μπορούμε να παρέχουμε καλύτερες ημερομηνίες παράδοσης και ποιότητα προϊόντων.

Ε: Ποια υπηρεσία μπορούμε να παρέχουμε;

Α: Προσφέρουμε προϊόντα υψηλής ποιότητας, πλήρη προσαρμογή ανάλογα με τις ανάγκες των χρηστών και τις υπηρεσίες επιβεβαίωσης δείγματος.

Καλωσορίστε το ερώτημά σας

Συνεργαζόμαστε με τους προμηθευτές πρώτων υλών για να εξασφαλίσουμε σταθερή ποιότητα και τιμολόγηση του προϊόντος. Όταν είναι απαραίτητο, μπορούμε να παράγουμε πρώτες ύλες οι ίδιοι. Εστιάζουμε στις ανάγκες των πελατών, παρέχοντας προϊόντα ποιότητας και υπηρεσίες μετά την πώληση για να δημιουργήσουμε αξία για τους συνεργάτες μας. Καλώς ήλθατε για να συζητήσετε τις ευκαιρίες συνεργασίας!

Συνιστώμενα προϊόντα